3D Scanning & Reverse Engineering Service

Irvine, CA

We offer 3D scanning, CAD, and reverse engineering services for your unique engineering applications.

For local customers, our team can come to your location to measure and scan your vehicle or component. If you're outside the area, you can ship your part to us for processing — we’ll handle the rest.

We use the Shining 3D Einstar scanner to capture precise 3D data of your part with exceptional accuracy and detail.

Our Scanning Process

-

Glossy, black, or transparent surfaces are coated with a scanning spray to be visible to the scanner.

-

Large, flat, or low-detail surfaces are tagged with reflective markers for better tracking.

-

Repetitive geometries such as wheels or turbine blades cannot be scanned due to pattern limitations at the moment.

Deliverables

We provide fast quotes and high-quality CAD models. Final files are available in your preferred format — scanned mesh, .sldprt, .stl, or .step — ready for design, manufacturing, or modification.

Typical Scope of Work

We offer precision 3D scanning and reverse engineering for a wide range of automotive and motorsport applications:

-

Engine Bay Scanning: Develop custom brackets, mounts, and optimize component placement.

-

Front-End Scanning: Capture bumper inlets and heat exchangers to design efficient ducting and cooling solutions.

-

Interior Scanning: Model cabin space for roll cage, seat, and pedal box design.

-

Wheel Well Scanning: Verify wheel, brake caliper, and fender clearance.

-

Suspension Geometry Analysis: Reconstruct camber, caster, toe curves, and motion ratios for chassis tuning.

-

Full Vehicle Scanning: Create watertight 3D models for CFD or aerodynamic development.

-

Body & Chassis Scanning: Support aero kit design, subframe modifications, and structural reinforcement.

-

Powertrain & Component Scanning: Digitize engine, transmission, or differential housings for custom fabrication or swaps.

-

Fitment & Quality Inspection: Validate part alignment and dimensional accuracy against CAD data.

For complex or unique projects, feel free to reach out at weidong@azzurroracing.com.

If a project falls outside my immediate scope, I’ll collaborate with the right individuals to deliver the solution.

Portfolio

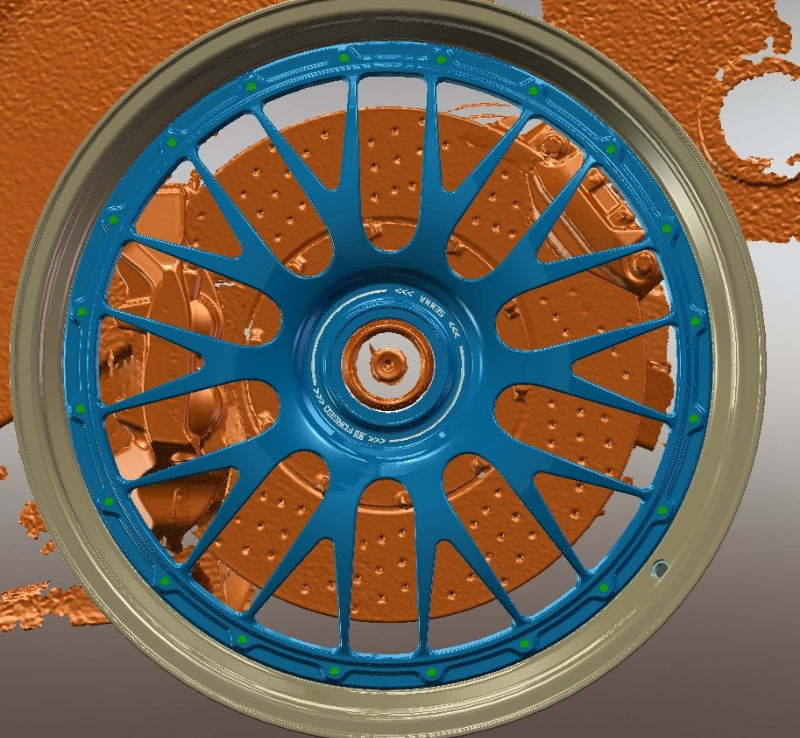

McLaren Senna — Two-Piece Forged Wheel Development

Commissioned by FSE LA / FSE Racing in collaboration with N-Zero Forged Wheels, we conducted a full 3D scan of the original wheel, center lock interface, and wheel well area.

The data was used to engineer a two-piece forged aluminum wheel with a maximum deep-concave spoke design while maintaining adequate caliper-to-spoke clearance. The design pays homage to the original BBS E88 three-piece wheels fitted on the blue 'Flemke' McLaren F1 #040.

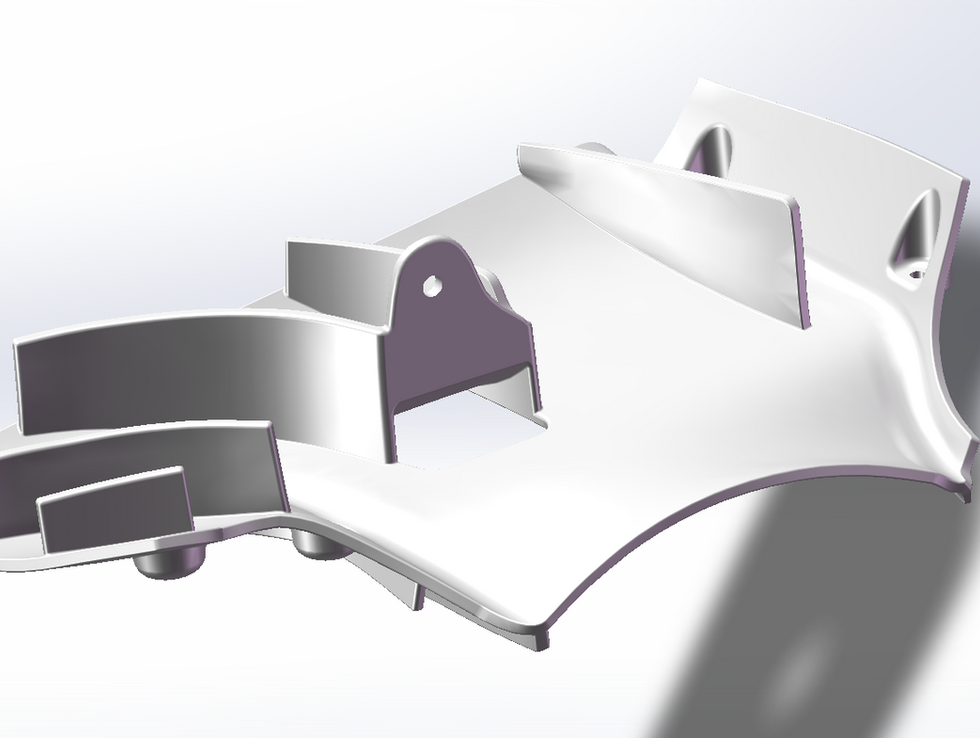

McLaren Senna - Reverse Engineering of Rear Brake Cooling Deflector

This project involved a rear brake cooling deflector from the McLaren Senna—a two-piece, injection-molded plastic assembly designed to channel air toward the center of the rear brake disc. Its intricate freeform surfaces made it one of the more challenging components to replicate accurately.

Because of the glossy black finish, the part was first coated with a scanning spray to improve surface visibility. Once scanned, our team rebuilt the geometry manually in CAD, converting the mesh data into a fully functional model.

Parts with this level of curvature and surface detail typically require around three weeks to reverse engineer. Most components take less time, but every project varies.

If you’d like to discuss your part, contact us for an accurate quote and timeline.

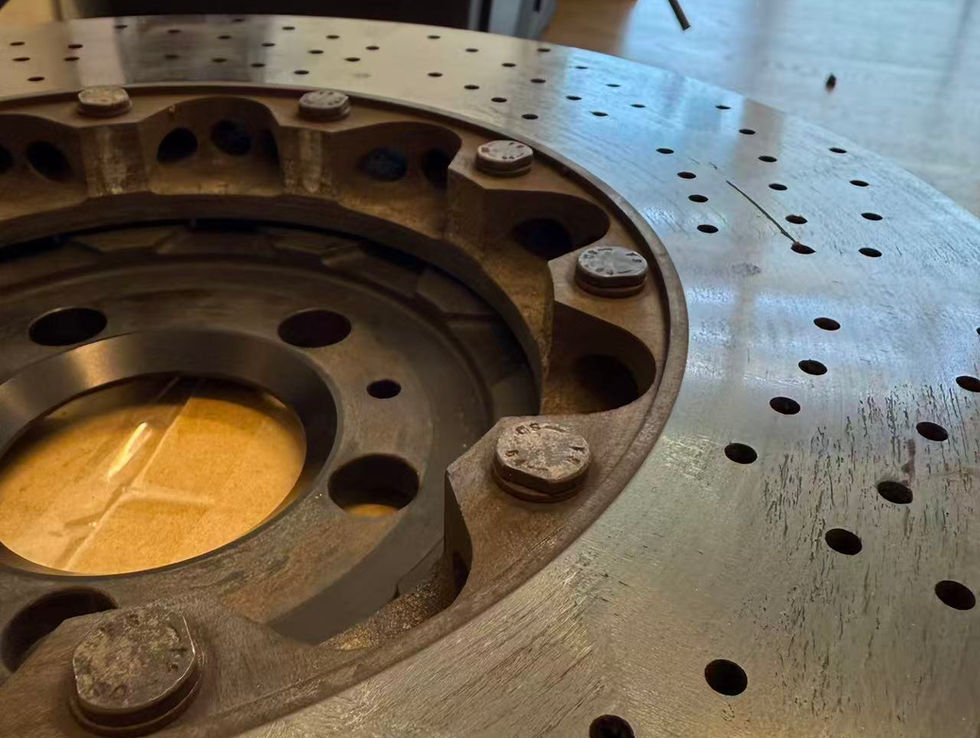

McLaren Senna - Carbon Ceramic Brake Hat

Commissioned by FSE LA / FSE Racing, we scanned and measured the brake rotor of a McLaren Senna to reverse engineer its brake hat assembly. The redesigned brake hat is engineered to pair with a proprietary carbon-ceramic disc, providing a cost-effective alternative for Senna owners who frequently track their cars.

This solution maintains the lightweight and thermal capacity of carbon-ceramic brakes while avoiding the expense of OEM replacements or the compromise of switching to steel rotors.

McLaren 765LT - Rear Wing Scan to Carbon Fiber Production

This one-off project was commissioned by a customer with a McLaren 720S seeking an upgraded rear wing. We performed a 3D scan of a McLaren 765LT rear wing and converted the data into CAD. The mounting geometry was modified to fit the 720S chassis, while preserving the original 765LT airfoil profile.

The finalized CAD model was sent to our partner manufacturer for billet CNC mold production, followed by pre-preg carbon fiber layup and autoclave curing—ensuring a precise surface finish, low resin content, and high structural quality.

Carbon fiber production is outsourced and accepted by cases. Both cost and lead time may vary depending on the complexity of the part. Pre-preg carbon fiber is significantly more expensive than hand laminate or vacuum infusion. For inquiries or custom projects, please contact us for details.

Ford Ranger Raptor - Tailgate Sealing Kit

Developed for FSE LA / FSE Racing, we scanned the tailgate opening of a 2024 Ford Ranger Raptor and partnered with a sheet metal manufacturer to develop a tailgate sealing kit. This product provides a practical solution for owners who frequently go off-road and want to prevent dust from entering the truck bed.

The design is done by East River Motorsport and fully engineered for mass production and OEM-level fitment.